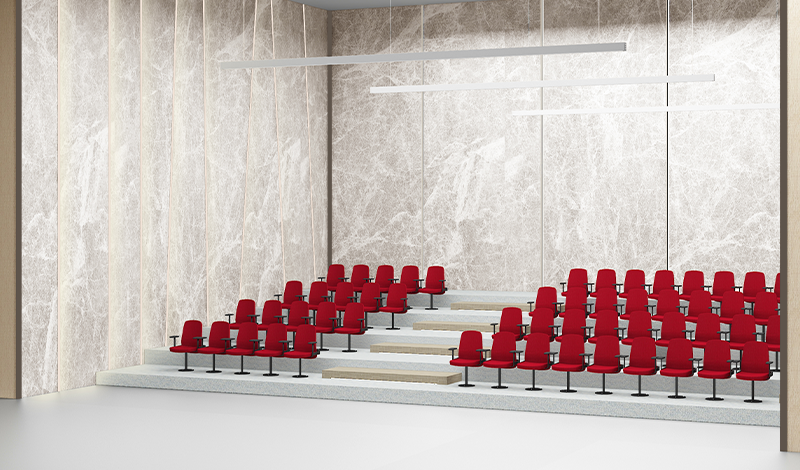

Auditorium Chairs

Built to provide the audience the ultimate comfort and ease, our range of auditorium seating uses the best of materials such as fabrics, cushion, plywood, plastic and MS powder coated that makes the product durable, safe, hygienic, and easy to maintain.

Arena

Mechanism: AutoSense slider/Tip-up & Back-push recliner chairs

Center to Center: 20 & 22 inches

Plywood (hardwood) with induction heating and high pressure pressed

ABS moulded housing for seat & back cushions

Armrest made of PP/ PPCP or semi rigid PU foam

Seat numbering at side of the chair

LED lights on sides along with aisles (additional cost)

Polyurethane Foam: Polyurethane injection moulded flexible Foam Seat & Back density 50-55 kg/m3

Springs: Torsion spring/spring steel IS-4454 1981 Grade III

Sheet Metal Components: HRCA/CRCA Sheet metal IS-1079 1994 Rectangular pipes

Powder Coating: Electrostatic epoxy coating thickness 70-80 microns

Aura Audi

The back is made up of 12mm thick (7 layers) hot pressed plywood and moulded foam thickness 40 mm upholstered with fabric

Understructure is made up of diameter 50.8×1.5 mm thick round MS tube, 48x19x2.5 mm thick oval MS tube, 8 mm thick MS plate and 3 mm thick MS plate welded together

Powder Coating is done in Black Colour having DFT – 50 to 80 microns

The seat is made up of 12mm thick (7 layers) hot pressed plywood and moulded seat foam upholstered with fabric

Seat Size: 495mm(W) X 500mm(D)

Foam made out of moulded Polyurethane foam

The arm-pad is made up of injection moulded from black polyurethane

Deck

Mechanism: Tip-up & Back-push recliner chairs

Center to Center: 20 inches

Plywood (hardwood) with induction heating and high pressure pressed

ABS moulded housing for seat & back cushions

Armrest made of PP/PPCP

LED lights on sides along with aisles (additional cost)

Polyurethane Foams: Polyurethane injection moulded flexible Foam Seat & Back density 50-55 kg/m3

Springs: Torsion spring/spring steel IS-4454 1981 Grade III

Sheet Metal Components: HRCA Bars

Powder Coating: Electrostatic epoxy coating thickness 70-80 microns

Galleria

Mechanism: AutoSense slider/Tip-up & Back-push recliner chairs

Center to Center: 21 & 22 inches

Plywood (hardwood) with induction heating and high pressure pressed

ABS moulded housing for seat & back cushions

Armrest made of PP/ PPCP or semi rigid PU foam

Seat numbering at side of the chair

LED lights on sides along with aisles (additional cost)

Polyurethane Foam: Polyurethane injection moulded flexible Foam Seat & Back density 50-55 kg/m3

Springs: Torsion spring/spring steel IS-4454 1981 Grade III

Sheet Metal Components: HRCA/CRCA Sheet metal IS-1079 1994 Rectangular pipes

Powder Coating: Electrostatic epoxy coating thickness 70-80 microns

Luxuria

Mechanism: AutoSense slider/Tip-up & Back-push recliner chairs

Center to Center: 22 & 24* inches (* – only for Armpad with full cladding)

Plywood (hardwood) with induction heating and high pressure pressed

ABS moulded housing for seat & back cushions

Armrest made of PP/ PPCP or semi rigid PU foam

Seat numbering at side of the chair

LED lights on sides along with aisles (additional cost)

Polyurethane Foam: Polyurethane injection moulded flexible Foam Seat & Back density 50-55 kg/m3

Springs: Torsion spring/spring steel IS-4454 1981 Grade III

Sheet Metal Components: HRCA/CRCA Sheet metal IS-1079 1994 Rectangular pipes

Powder Coating: Electrostatic epoxy coating thickness 70-80 microns

Mezzanine

Mechanism: Tip-up & Back-push recliner chairs

Center to Center: 20 inches

Plywood (hardwood) with induction heating and high pressure pressed

ABS moulded housing for seat & back cushions

Armrest made of PP/PPCP

LED lights on sides along with aisles (additional cost)

Polyurethane Foams: Polyurethane injection moulded flexible Foam Seat & Back density 50-55 kg/m3

Springs: Torsion spring/spring steel IS-4454 1981 Grade III

Sheet Metal Components: HRCA Bars

Powder Coating: Electrostatic epoxy coating thickness 70-80 microns